Zebra printer Error Condition Paper Out causes and solutions

Description

This articles discusses the Error Condition Paper Out on Zebra printers.

The error, Error Condition Paper Out can have several causes.

-

No label stock is loaded into the printer

-

Label

A label is a design area on the computer screen where a label format is created or edited. stock is not loaded properly and is not aligned with the stock sensor

A label is a design area on the computer screen where a label format is created or edited. stock is not loaded properly and is not aligned with the stock sensor -

The printer is set to gap stock, but it is loaded with continuous stock.

-

The maximum label length is set too short.

-

The stock sensor does not have the correct sensitivity setting, or is not functioning properly.

Corrective action

1. No label stock is loaded into the printer.

Install label stock into the printer. This is the intent of the sensor, to indicate that the roll of labels has been used up.

2. Label stock is not loaded prperly and is not aligned with the stock sensor.

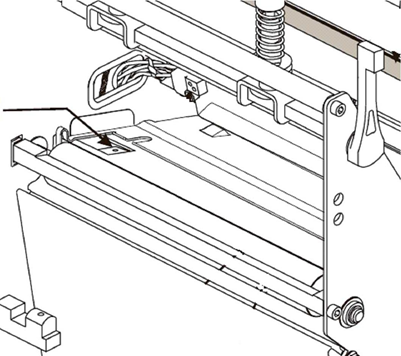

The label stock must cover the eye of sensor and should be fed under the feed guide so that the paper is as close to the sensor as possible

3. The printer is set to gap stock, but it is loaded with continuous stock.

If the printer is set for non-continuous (or die cut) stock, but continuous stock is loaded in the printer,

then the printer will be trying to find a gap between labels.

When the printer reaches it's maximum label size, if it doesn't find a gap it will report the Paper Out error condition.

The MEDIA TYPE setting must match the actual media loaded for the sensor to work properly.

4. If maximum LABEL LENGTH setting is set too short it can cause a false Paper Out error to occur.

If the gap is not sensed before the maximum label length is reached, then the Paper Out error condition will be reported.

5. The stock sensor does not have the correct sensitivity setting, or is not functioning properly.

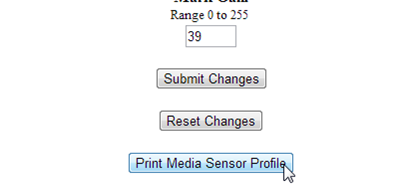

The Zebra printer has the ability to print out a representation of what the sensor is seeing via the Print Media Sensor Profile button.

This will print a bar graph on a label showing the percentage of light sensed through the label stock and backing:

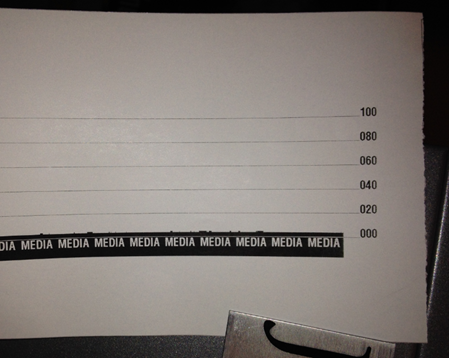

In this image a continuous label stock is being read at about 5%, this is a proper read for this kind of paper.

A sensor that is not functioning properly will show a continuous high value seen through the stock.

This is stock that is not being read properly by the media sensor.

- Adjusting the sensitivity of the media sensor may help.

- Or, this printer may need to be serviced.

A properly read Non-Continuous label stock will have a sensor profile that looks like the image below.

Best profile, there is no "Noise" and a distinct difference between the readings for the backing only and the backing plus media.

In this case either the label stock is fed wrong, or the sensor is blocked, or the sensor has a malfunction and should be serviced.

Additional Information

- Document SO8310

Article Number

2013109

Versions

All Loftware versions

Environment

Zebra printers